What can be done with beverage cartons, also known as Tetra Pak?

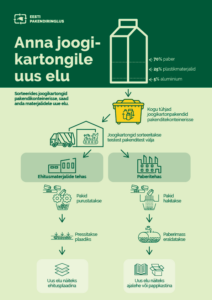

Beverage cartons – simply put, Tetra Paks or multi-packs, are a type of packaging primarily used for milk, kefir, yogurt, juices, or even wines. This packaging type is valuable because it can be used to make new products. Recycling beverage cartons is an important step in saving natural resources by turning packaging waste into new products. Beverage cartons typically consist of several layers: paper (about 70% of the packaging composition), plastic (about 25% of the packaging composition), and a thin aluminum layer (about 5% of the packaging composition). Although this combination of materials makes the packaging strong and leak-proof, it also makes recycling more challenging.

Fortunately, there are solutions for recycling, and separating these types of packaging from mixed household waste is definitely an important and valuable action.

How do beverage carton packages make it into recycling?

1. Sorting at home

- Beverage cartons generally do not need to be washed: for example, milk, juice, or wine cartons do not need to be washed, but it’s important that they are empty. If there’s residue like kefir or yogurt on the walls of the carton, rinse it out with a small amount of water.

- The next step for sending the beverage carton to its second life is to place it in the appropriate recycling container.

2. Pre-treatment

- The contents of the recycling container are transported to a sorting plant, where different types of materials are separated on the sorting line and pressed together for recycling. Once a truckload of beverage cartons is collected, a vehicle is called to pick them up and send them to the plant.

3. Beverage cartons are mainly processed in two ways

- In paper mills – Once the cartons arrive, they are first shredded into pieces, then water is added, causing the paper pulp to separate from the plastic and aluminum. The plastic and aluminum are removed from the mixture, leaving behind clean, strong, long-fibered paper pulp. Once the pulp is cleaned, it is mixed with new wood pulp if necessary to improve the paper’s strength. The paper pulp is directed into a paper machine, where it is spread into a thin layer on rollers. Excess water is removed through pressing and drying, forming strong and dry paper. The dried and processed paper is rolled onto large rolls or cut into sheets. The finished paper is sent to manufacturers, who create new paper products from it, such as newspapers, stationery, or cardboard boxes.

- In construction material factories – Construction boards are made. The beverage cartons are crushed into smaller pieces to facilitate further processing. The entire packaging mass moves to the molding process, where it is pressed under high temperature and pressure, melting the plastic layer and binding all materials together into a strong board. The finished boards are cut into appropriate sizes according to the user’s needs. This construction material resembles particle board and has similar uses: as wall panels, partition walls, or furniture boards.

Beverage cartons collected and ready for delivery to the recycling plant.

Construction material made from beverage cartons.

Why is recycling beverage cartons important?

- Resource conservation: Recycling paper fibers reduces the need for new wood pulp, helping to preserve forests.

- Energy savings: The recycling process requires less energy compared to the production of new materials.

- Reduction of landfill waste: Recycling cartons keeps them out of landfills and reduces environmental pollution.